|

Di seguito gli interventi pubblicati in questa sezione, in ordine cronologico.

Scientists from the Universities of Sheffield and Cambridge have published research on manufacturing ultra-cheap solar energy panels for large-scale domestic and industrial use. The idea is to use high-volume printing to produce nanoscale films of polymer solar cells --- cells more than a 1,000 times thinner than the width of a human hair.

Now we've heard of thin-film and other solar advancements before. But the existing technology, with polymer solar cells, is only 7-8% efficient. The next step is to develop cells that are 10% efficient, or more, the scientists say.

The researchers used the ISIS Neutron Source and Diamond Light Source at STFC Rutherford Appleton Laboratory in Oxfordshire to study the crystallinity of the material and examine its composition profile.

According to Physorg.com:

"The study showed that when complex mixtures of molecules in solution are spread onto a surface, like varnishing a table-top, the different molecules separate to the top and bottom of the layer in a way that maximises the efficiency of the resulting solar cell."

Robert Dalgliesh, one of the ISIS scientists involved in the work, said, "... Using neutron beams at ISIS and Diamond's bright X-rays, we were able to probe the internal structure and properties of the solar cell materials non-destructively. By studying the layers in the materials which convert sunlight into electricity, we are learning how different processing steps change the overall efficiency and affect the overall polymer solar cell performance."

This study, published in the journal Advanced Energy Materials, used a photovoltaic blend of materials called PCDTBT: PCBM, and based on the Nobel-prize-winning, 1996 chemistry work of professors Richard Smalley and Harry Kroto.

The research was funded with a grant from the Engineering and Physical Sciences Research Council, and a new grant to carry out further studies has been awarded. The ISIS and Diamond Light Source devices are affiliated with the Science & Technology Facilities Council.

Source: TreeHugger

The findings show that the biomaterial could possibly be used in the future detection of toxins, explosives, pollutants, and medicines.

Detection devices have superior sensitivity when the sensor itself can be packaged at high density. Certain proteins that are found in the membranes of cells can act as sensors. However, the density with which cellular membranes can be packed in a sensor of a defined volume can limit the application. In this study, use was made of a particular form of matter, referred to as a liquid crystal or mesophase, that behaved as a densely packed mimic for cellular membranes.

Certain naturally occurring lipids or fats, when combined with water spontaneously form liquid crystals. One of these lipids called monoolein is a product of fat digestion. The liquid crystalline cubic phase that monoolein forms, when wet, has the lipid arranged as a bilayer just two molecules thick that is bathed on either side by water. This hydrated bilayer resembles the membrane that surrounds the cells in living organisms. The cubic phase is particularly notable as a liquid crystal in the extraordinary density with which it packages the membrane and the enormous surface area that it has. Thus, for example, a mere thimbleful of the cubic phase has enough surface area to cover a football field.

The research conducted by Trinity’s Professor of Membrane Structural and Functional Biology, Martin Caffrey and Research Associate Dr Dianfan Li in the School of Medicine and School of Biochemistry & Immunology used the cubic phase; but the cubic phase made from hydrated fat alone was useless. It needed to have a membrane protein sensor incorporated into it and the protein needed to be active. The test sensor used in the research was a membrane protein, referred to as DgkA. DgkA is an enzyme that interconverts the fatty components of natural cellular membranes. The enzyme was produced in E. coli bacteria, using recombinant DNA technology, as an inactive or dead ‘scrambled egg’ type of insoluble aggregate. ‘Life’ was breathed back into the enzyme by dissolving the aggregated protein in a soapy solution and inserting it into the membrane of the cubic phase. In this new and quite artificial environment the researchers showed that the protein had regained its original native enzyme activity and that it could behave as a model sensor.

The research sets the stage for the exploitation of this most extraordinary of biomaterials. These include its use in high density, high sensitivity biosensors for the detection of biological molecules such as hormones, proteins, carbohydrates, and lipids, as well as toxins, explosives, pollutants, and drugs.

Source: Trinity College Dublin

Scientists from Harvard University trained pigeons to fly through an artificial forest with a tiny camera attached to their heads, literally giving a birds-eye view. "Attaching the camera to the bird as well as filming them from either side means we can reconstruct both what the bird sees and how it moves," says Dr. Huai-Ti Lin, a lead researcher for this work who has special insight into flying as he is a remote control airplane pilot himself.

The pigeons were fitted with a tiny head-camera before they flew through the artificial forest.

The methods pigeons use to navigate through difficult environments could be used as a model for auto-pilot technology. Pigeons, with >300 degree panoramic vision, are well suited to this task because this wrap-round vision allows them to assess obstacles on either side. They can also stabilise their vision and switch rapidly between views using what is called a "head saccade", a small rapid movement of the head.

The researchers also showed that the birds have other skills that would be important for auto-piloted machines, for example they tend to choose the straightest routes. "This is a very efficient way of getting through the forest, because the birds have to do less turns and therefore use less energy but also because they reach the other side quicker," says Dr Lin. "Another interesting finding is that pigeons seems to exit the forest heading in exactly the same direction as when they entered, in spite of all the twist and turns they made in the forest."

This image shows a pigeon, fitted with a camera, about to fly through the artificial forest that can be seen in the background.

When using a robot or an unmanned air-craft it would be invaluable to simply provide it with the coordinates of the destination without having to give it detailed information of all the obstacles it might meet on the way. "If we could develop the technology to follow the same methods as birds we could let the robot get on with it without giving it any more input," says Dr. Lin.

Source: EurekAlert

To reach this record, Sergei Zherlitsyn and his colleagues at the High Magnetic Field Laboratory Dresden (HLD) developed a coil weighing about 200 kilograms in which electric current create the giant magnetic field – for a period of a few milliseconds. The coil survived the experiment unscathed.

With this record, we’re not really that interested in reaching top field values, but instead in using it for research in materials science, ”explains Joachim Wosnitza, the HLD’s Director. The scientists are actually proud of being the first user lab worldwide to make such high magnetic fields available for research. The more powerful a magnetic field is, the more precisely the scientists can examine those substances which are used for innovative electronic components or for so-called superconductors which conduct electricity without any resistance. Such high magnetic fields are generated by passing an electric current through a copper coil.

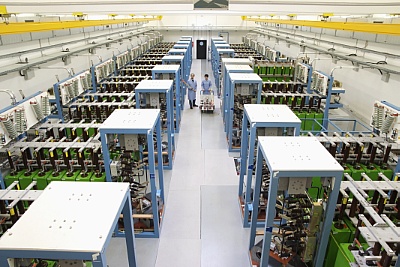

The capacitor bank of the Dresden High Magnetic Field Laboratory.

But the magnetic field also influences the electric current because it tries to push the electric current out of the coil. The stronger the current flows, the more powerful these forces are. “At 25 Tesla, the copper would be torn apart,” Joachim Wosnitza describes a potential scenario of this conflict between the magnetic field and the metal. In comparison: A standard commercial refrigerator magnet has 0.05 Tesla.

In order to examine as closely as possible the electric charge in the materials of tomorrow, researchers need higher magnetic fields with, for example, 90 or 100 Tesla. “At 100 Tesla, though, the Lorentz force inside the copper would generate a pressure which equals 40,000 times the air pressure at sea level,” calculates Joachim Wosnitza. These forces would tear copper apart like an explosion. That is why researchers use specific copper alloys which can withstand ten thousand times the atmospheric pressure. They then add a corset made from a special fiber that is typically used for bulletproof vests and which holds the alloy together from the outside. The HZDR technicians wind six of these special wires with corsets into a coil that has a hollow space of 16 millimeters at its center. This permits the generation of 50 Tesla within this special coil when a brief but powerful electric pulse flashes through the copper – a process that is over after a mere 0.02 seconds.

Magnetic coil.

But that’s still, though, far away from the world record of 89 Tesla which the US Americans held in Los Alamos for several years. And that is why the technicians put a second coil consisting of twelve layers of copper wire around the first one. This wire, though, can only withstand 2,500 times the atmospheric pressure. But protected by a plastic corset, a current pulse lasting only a fifth of a second suffices to create a 40 tesla magnetic field inside the coil. Together with the 50 Tesla of the inner coil, this adds up to the world record of more than 90 Tesla. Covered by a steel jacket, this double coil has a height of 55 centimeters and a diameter of 32 centimeters; thus, resembling a fairly large water bucket. For several weeks, the HZDR technicians worked on the coil which not only set the world record, but which will also permit many future studies of new materials in the record magnetic field.

For such experiments, researchers are flocking to Dresden not only from Regensburg, Garching, and Karlsruhe, but also from all over Europe. Even Japanese and US American scientists are already making reservations at the HZDR so that they can analyze their materials here. And since today the existing five rooms equipped with similar coils can no longer handle the crowds of researchers, an additional six of these “pulse cells” will be built by 2015. Magnetic-field research at the HZDR actually continues to expand even after the world record.

Source: Helmholtz-Zentrum Dresden-Rossendorf

IBM researchers have developed a programming trick that makes it possible to more reliably store large amounts of data using a promising new technology called phase-change memory. The company hopes to start integrating this storage technology into commercial products, such as servers that process data for the cloud, in about five years.

Like flash memory, commonly found in cell phones, phase-change memory is nonvolatile. That means it doesn't require any power to store the data. And it can be accessed rapidly for fast boot-ups in computers and more efficient operation in general. Phase-change memory has a speed advantage over flash, and Micron and Samsung are about to bring out products that will compete with flash in some mobile applications.

Long-term memory: Each cell in this 200,000-cell phase-change memory chip can store multiple bits of data reliably over a period of several months.

These initial products will use memory cells that store one bit each. But for phase-change memory to be cost-competitive for broader applications, it will need to achieve higher density, storing multiple bits per cell. Greater density is necessary for IBM to achieve its goal of developing phase-change memory for high-performance systems such as servers that process and store Internet data much faster.

The IBM work announced today offers a solution. In the past, researchers haven't been able to make a device that uses multiple bits per cell that works reliably over months and years. That's because of the properties of the phase-change materials used to store the data. Scientists at IBM Research in Zurich have developed a software trick that allows them to compensate for this.

Each cell in these data-storage arrays is made up of a small spot of phase-change materials sandwiched between two electrodes. By applying a voltage across the electrodes, the material can be switched to any number of states along a continuum from totally unstructured to highly crystalline. The memory is read out by using another electrical pulse to measure the resistance of the material, which is much lower in the crystalline state.

To make multibit memory cells, the IBM group picked four different levels of electrical resistance. The trouble is that over time, the electrons in the phase-change cells tend to drift around, and the resistance changes, corrupting the data. The IBM group has shown that they can encode the data in such a way that when it's read out, they can correct for drift-based errors and get the right data.

The IBM group has shown that error-correcting code can be used to reliably read out data from a 200,000-cell phase-change memory array after a period of six months. "That's not gigabits, like flash, but it's impressive," says Eric Pop, professor of electrical engineering and computer sciences at the University of Illinois at Urbana-Champaign. "They're using a clever encoding scheme that seems to prolong the life and reliability of phase-change memory."

For commercial products, that reliability timescale needs to come up to 10 years, says Victor Zhirnov, director of special projects at the Semiconductor Research Corporation. IBM says it can get there. "Electrical drift in these materials is mostly problematic in the first microseconds and minutes after programming," says Harris Pozidis, manager of memory and probe technologies at IBM Research in Zurich. The problem of drift can be statistically accounted for in the IBM coding scheme over whatever timeframe is necessary, says Pozidis, because it occurs at a known rate.

But phase-change memory won't be broadly adapted until power consumption can be checked, says Zhirnov. It still takes much too much energy to flip the bits in these arrays. That's due to the way the electrodes are designed, and many researchers are working on the problem. This spring, Pop's group at the University of Illinois demonstrated storage arrays that use carbon nanotubes to encode phase-change memory cells with 100 times less power.

Source: Technology Review

University of Illinois engineers have developed a silver-inked rollerball pen capable of writing electrical circuits and interconnects on paper, wood and other surfaces. The pen is writing whole new chapters in low-cost, flexible and disposable electronics.

Led by Jennifer Lewis, the Hans Thurnauer professor of materials science and engineering at the U. of I., and Jennifer Bernhard, a professor of electrical and computer engineering, the team published its work in the journal Advanced Materials.

"Pen-based printing allows one to construct electronic devices 'on-the-fly,' " said Lewis, the director of the Frederick Seitz Materials Research Laboratory at the U. of I. "This is an important step toward enabling desktop manufacturing (or personal fabrication) using very low cost, ubiquitous printing tools."

While it looks like a typical silver-colored rollerball pen, this pen's ink is a solution of real silver. After writing, the liquid in the ink dries to leave conductive silver pathways -- in essence, paper-mounted wires. The ink maintains its conductivity through multiple bends and folds of the paper, enabling devices with great flexibility and conformability.

Metallic inks have been used in approaches using inkjet printers to fabricate electronic devices, but the pen offers freedom and flexibility to apply ink directly to paper or other rough surfaces instantly, at low cost and without programming.

"The key advantage of the pen is that the costly printers and printheads typically required for inkjet or other printing approaches are replaced with an inexpensive, hand-held writing tool," said Lewis, who is also affiliated with the Beckman Institute for Advanced Science and Technology.

The ability to create freestyle conductive pathways enables new possibilities in art, disposable electronics and folded three-dimensional devices. For example, the researchers used the silver pen to sketch a copy of the painting "Sae-Han-Do" by Jung Hee Kim, which portrays a house, trees and Chinese text. The ink serves as wiring for an LED mounted on the roof of the house, powered by a five-volt battery connected to the edge of the painting. The researchers also have demonstrated a flexible LED display on paper, conductive text and three-dimensional radio-frequency antennas.

Next, the researchers plan to expand the palette of inks to enable pen-on-paper writing of other electronic and ionically conductive materials.

The U.S. Department of Energy supported this work. Co-authors were graduate student Analisa Russo and postdoctoral researchers Bok Yeop Ahn, Jacob Adams and Eric Duoss.

Source: ScienceDaily

In order to realize the full potential of advanced biofuels that are derived from non-food sources of lignocellulosic biomass—e.g., agricultural, forestry, and municipal waste, and crops such as poplar, switchgrass and miscanthus—new technologies that can efficiently and cost-effectively break down this biomass into simple sugars are required. Existing biomass pretreatment technologies are typically derived from the pulp and paper industry and rely on dilute acids and bases to break down the biomass. The treated biomass product is then exposed to biological catalysts, or enzymes, to liberate the sugars.

A new class of solvents, referred to as ionic liquids, have been reported to be much more efficient in treating the biomass and enhancing the yield of sugars liberated from it. While ionic liquids are useful for breaking down biomass, they can also hinder the ability of the cellulases (usually derived from fungi) used to produce sugars after pretreatment. Ionic liquids are a liquid form of salt that will inactivate enzymes by interfering with the folding of polypeptides—the building-blocks of proteins. To help identify new enzymes that are tolerant of ionic liquids, researchers from the U.S. Department of Energy (DOE) Joint Genome Institute (JGI) and the Joint BioEnergy Institute (JBEI) at DOE's Lawrence Berkeley National Laboratory are turning to those found in the complete genome sequences of halophilic (salt-tolerant) organisms.

As a test of a bioenergy-related application of DNA sequencing and enzyme discovery, US Department of Energy Joint Genome Institute researchers led by the DOE JGI Director Eddy Rubin, and colleagues from the Joint BioEnergy Institute at DOE's Lawrence Berkeley National Laboratory employed a cellulose-degrading enzyme from a salt-tolerant microbe that was isolated from the Great Salt Lake. Credit: David Gilbert, DOE JGI

As a test of this bioenergy-related application of DNA sequencing and enzyme discovery, researchers led by the Director of the DOE JGI, Eddy Rubin, and the Vice-President of the JBEI Deconstruction Division, Blake Simmons, employed a cellulose-degrading enzyme from a salt-tolerant microbe that was isolated from the Great Salt Lake. The microbe in question, Halorhabdus utahensis, is from the branch of the tree of life known as Archaea; H. utahensis was isolated from the natural environment at the Great Salt Lake and sequenced at the DOE JGI as part of the Genomic Encyclopedia of Bacteria and Archaea (GEBA) project.

"This is one of the only reports of salt-tolerant cellulases, and the only one that represents a true 'genome-to-function' relevant to ionic liquids from a halophilic environment," said Simmons of the study published June 30, 2011 in Green Chemistry. "This strategy enhances the of identifying true obligatory halophilic enzymes." Such salt-tolerant enzymes, particularly cellulases, offer significant advantages for industrial utility over conventional enzymes.

In collaboration with Jerry Eichler from Ben Gurion University of the Negev in Israel they cloned and expressed a gene from H. utahensis in another haloarchaeal microbe, and were able to identify a salt-dependent enzyme that can tolerate high temperatures and is resistant to ionic liquids. "This project has established a very important link between genomic science and the realization of enzymes that can handle very demanding chemical environments, such as those present in a biorefinery," said Simmons.

The group plans to expand this research to develop a full complement of enzymes that is tailored for the ionic liquid process technology with the goal of demonstrating a complete biomass-to-sugar process, one they hope can enable the commercial viability of advanced biofuels.

Source: PhysOrg

Physicists at the University of Luxembourg have developed a new method to improve the electrical conductivity of polymeric composites. Polymeric composites consist of two or more materials and are used for example to shield off electrostatics in airplanes. By introducing additives into polymeric composites, favorable properties can be achieved. For instance, they develop favourable electrical properties when reinforced with carbon nanotubes. Such composites are used to make flat-panel displays and solar cells more efficient.

The researchers in Luxembourg, in cooperation with scientists from the Netherlands, have studied the electrical percolation of carbon nanotubes in a polymer matrix and shown the percolation threshold -- the point at which the polymer composite becomes conductive -- can be considerably lowered if small quantities of a conductive polymer latex are added. The simulations were done in Luxembourg, while the experiments took place at Eindhoven University.

"In this project, the idea is to use as little as possible carbon nanotubes and still benefit from their favourable properties," says the project leader at the University of Luxembourg, Prof. Tania Schilling, "we have discovered that, by adding a second component, we could make use of the resulting interactions to reach our goal." By mixing finely dispersed particles, so-called colloidal particles, of differing shapes and sizes in the medium, system-spanning networks form: the prerequisite for electrically conductive composites.

The recent finding of the materials scientists of the University of Luxembourg was published in the peer-reviewed, scientific journal Nature Nanotechnology. This finding is a result of a cooperation of scientists at the University of Luxembourg, the Technische Universiteit Eindhoven and the Dutch Polymer Institute.

Source: Science Daily

When fully developed as a hand-held, portable sensor, like something you might see in a science fiction movie, it will provide a whole diagnostic laboratory on a single chip.

The research could revolutionize the size, speed and accuracy of chemical detection systems around the world.

New findings on this "microfluidic sensor" were recently reported inSensors and Actuators B: Chemical, a professional journal, and the university is pursuing a patent on related technologies. The collaborative studies were led by Vincent Remcho, an OSU professor of chemistry, and Pallavi Dhagat, an assistant professor in the OSU School of Electrical Engineering and Computer Science.

The key, scientists say, is tapping into the capability of ferromagnetic iron oxide nanoparticles -extraordinarily tiny pieces of rust. The use of such particles in the new system can not only detect chemicals with sensitivity and selectivity, but they can be incorporated into a system of integrated circuits to instantly display the findings.

This diagram illustrates how a new sensor technology developed at Oregon State University might work using magnetic beads. (Credit: Graphic courtesy of Oregon State University)

"The particles we're using are 1,000 times smaller than those now being used in common diagnostic tests, allowing a device to be portable and used in the field," said Remcho, who is also associate dean for research and graduate programs in the OSU College of Science.

"Just as important, however, is that these nanoparticles are made of iron," he said. "Because of that, we can use magnetism and electronics to make them also function as a signaling device, to give us immediate access to the information available."

According to Dhagat, this should result in a powerful sensing technology that is fast, accurate, inexpensive, mass-producible, and small enough to hold in your hand.

"This could completely change the world of chemical assays," Dhagat said.

Existing assays are often cumbersome and time consuming, using biochemical probes that require expensive equipment, expert personnel or a complex laboratory to detect or interpret.

In the new approach, tiny nanoparticles could be attached to these biochemical probes, tagging along to see what they find. When a chemical of interest is detected, a "ferromagnetic resonance" is used to relay the information electronically to a tiny computer and the information immediately displayed to the user. No special thin films or complex processing is required, but the detection capability is still extremely sensitive and accurate.

Essentially, the system might be used to detect almost anything of interest in air or water. And the use of what is ordinary, rusty iron should help address issues of safety in the resulting nanotechnology product.

Rapid detection of chemical toxins used in bioterrorism would be possible, including such concerns as anthrax, ricin or smallpox, where immediate, accurate and highly sensitive tests would be needed. Partly for that reason, the work has been supported by a four-year grant from the Army Research Laboratory, in collaboration with the Oregon Nanoscience and Microtechnologies Institute.

However, routine and improved monitoring of commercial water treatment and supplies could be pursued, along with other needs in environmental monitoring, cargo inspections, biomedical applications in research or medical care, pharmaceutical drug testing, or even more common uses in food safety.

Other OSU researchers working on this project include Tim Marr, a graduate student in electrical engineering, and Esha Chatterjee, a graduate chemistry student.

The concept has been proven in the latest study, scientists say, and work is continuing with microfluidics research to make the technology robust and durable for extended use in the field.

Source: ScienceDaily

3D printing technology is a fast and affordable way to build 3D models for neurosurgical planning. Radiologists are able to transform ultra high-resolution CT patient images into 3D solid models using a 3D color printer commonly used in architecture, engineering and construction.

An advantage of 3-D models is that they identify defects that 2-D images do not, which helps radiologists view a clearer impression of the image. With increasing frequency, surgeons and other physicians, and patients alike, request assistance from radiologists in order to identify complex morphologies demonstrated on imaging studies.

"We are applying a technique that has many uses in other industries to aid surgeons in planning procedures on complicated anatomy and pathology as well as help them communicate with patients and their families. Tripler doctors were sending data from Hawaii to the mainland US to have models made at great expense and considerable time. Other radiologists may find these resources in an architect's office or at a factory using 3D printing to make prototypes for just about anything you can fit in a shoebox," said Michelle Yoshida, MD, one of the authors of the exhibit.

Source: ScienceDaily

|