Now, the Whitesides group at Harvard University has developed a force sensor for a microelectromechanical system (MEMS) using paper as the structural material [Whitesides et al., Lab Chip(2011) doi: 10.1039/c1lc20161a].

MEMS devices are becoming increasingly common in research, in industrial settings and in medical diagnostics. Several companies have now developed MEMS for a wide range of applications: digital micromirror devices (DMD, Texas Instruments), accelerometers for firing vehicle airbags (Analog Devices and Motorola), and pressure/?ow sensors for industrial uses (Honeywell). However, while such devices are based on semiconductor materials, such as silicon, they will remain expensive and require complex manufacturing facilities and clean rooms for their construction.

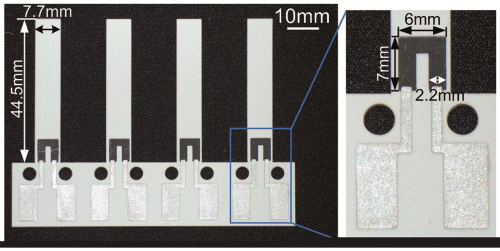

Photograph of an array of four devices. Image courtesy of Xinyu Liu, Whitesides. Reproduced from Lab Chip (2011) doi: 10.1039/c1lc20161a by permission of The Royal Society of Chemistry.

Whitesides and colleagues hope to circumvent such obstacles by finding inexpensive alternatives to silicon and its ilk and precluding the need for complex and costly fabrication processes. As such, they have now developed a prototypical MEMS device; a paper-based piezoresistive force sensor, demonstrating that a readily available and easy to prepare material can be used to build useful devices, albeit with perhaps poorer performance than conventional MEMS. The same approach has also been used to develop a paper-based weighing balance.

The group emphasizes that the force sensor is simple to construct, taking less than an hour with no special facilities or equipment; a paper cutter and painting knife are all that are needed. Material costs for each device are of the order of a few cents. When asked about the novelty and utility of this work, Whitesides remarked to Materials Today that, "Sometimes things that obviously can't work have a mind of their own and work anyway."

The team has shown that the force sensor can measure the properties of a soft material with moderate, but useful, performance compared to conventional MEMS, giving a resolution of 120 micronewtons and a 16 millinewton measurement range. The paper-based balance can measure up to 15 grams and has a resolution of 0.39 grams.

These low-cost, portable and disposable paper-based MEMS devices could be used as single-use sensors in analytical applications, for instance in the mechanical characterization of tissues in medical diagnostics and in food viscosity measurements. The researchers add that in contrast to silicon-based MEMS, a paper-based device might be too sensitive to high temperatures, atmospheric components , such as water vapor, ozone, peroxides, etc. However, in some contexts such sensitivities might also be exploited for other applications of the device, such as humidity sensors or an ad hoc chemical detector for emergencies.

Source: Materials Today