|

Di seguito gli interventi pubblicati in questa sezione, in ordine cronologico.

The success of the project to create a 're-programmable cell' could revolutionise synthetic biology and would pave the way for scientists to create completely new and useful forms of life using a relatively hassle-free approach.

Professor Natalio Krasnogor of the University's School of Computer Science, who leads the Interdisciplinary Computing and Complex Systems Research Group, said: "We are looking at creating a cell's equivalent to a computer operating system in such a way that a given group of cells could be seamlessly re-programmed to perform any function without needing to modifying its hardware."

"We are talking about a highly ambitious goal leading to a fundamental breakthrough that will, -- ultimately, allow us to rapidly prototype, implement and deploy living entities that are completely new and do not appear in nature, adapting them so they perform new useful functions."

The game-changing technology could substantially accelerate Synthetic Biology research and development, which has been linked to myriad applications -- from the creation of new sources of food and environmental solutions to a host of new medical breakthroughs such as drugs tailored to individual patients and the growth of new organs for transplant patients.

The multi-disciplinary project, funded with a leadership fellowship for Professor Krasnogor worth more than Ł1 million from the Engineering and Physical Sciences Research Council (EPSRC), involves computer scientists, biologists and chemists from Nottingham as well as academic colleagues at other universities in Scotland, the US, Spain and Israel.

The project -- Towards a Biological Cell Operating System (AUdACiOuS) -- is attempting to go beyond systems biology -- the science behind understanding how living organisms work -- to give scientists the power to create biological systems. The scientists will start the work by attempting to make e.coli bacteria much more easy to program.

Professor Krasnogor added: "This EPSRC Leadership Fellowship will allow me to transfer my expertise in Computer Science and informatics into the wet lab.

"Currently, each time we need a cell that will perform a certain new function we have to recreate it from scratch which is a long and laborious process. Most people think all we have to do to modify behaviour is to modify a cell's DNA but it's not as simple as that -- we usually find we get the wrong behaviour and then we are back to square one. If we succeed with this AUdACiOuS project, in five years time, we will be programming bacterial cells in the computer and compiling and storing its program into these new cells so they can readily execute them.

"Like for a computer, we are trying to create a basic operating system for a biological cell."

Among the most fundamental challenges facing the scientists will be developing new computer models that more accurately predict the behaviour of cells in the laboratory.

Scientists can already programme individual cells to complete certain tasks but scaling up to create a larger organism is trickier.

The creation of more sophisticated computer modelling programmes and a cell that could be re-programmed to fulfil any function without having to go back to the drawing board each time could largely remove the trial and error approach currently taken and allow synthetic biology research to take a significant leap forward.

The technology could be used in a whole range of applications where being able to modify the behaviour of organisms could be advantageous. In the long run, this includes the creation of new microorganisms that could help to clean the environment for example by capturing carbon from the burning of fossil fuel or removing contaminants, e.g. arsenic from water sources. Alternatively, the efficacy of medicine could be improved by tailoring it to specific patients to maximise the effect of the drugs and to reduce any harmful side effects.

Source: University of Nottingham

The World Diabetes Foundation estimated that some 285 million people, or around 6 percent of the world's adult population, were living with diabetes in 2010. For type 1 diabetics and up to 27 percent of type 2 diabetics, that means daily insulin injections, which can be uncomfortable and inconvenient. Since most people would rather pop a pill than get a shot, researchers have been trying to develop an oral form of insulin. However, this has proven difficult because insulin is a protein that is broken down in the stomach and gut. Now a team of researchers from Australia's Curtin University has found an insulin substitute to treat diabetes orally that they hope could help take the needle out of diabetes for many people.

In an effort to find a compound that emulates the molecular map of insulin, Professor Erik Helmerhorst and his colleagues at Curtin University in research undertaken with Australian pharmaceutical company Epichem searched the structures of three million compounds.

"We took a 3D molecular map of insulin and identified the key features within this map that are needed for insulin's activity," Prof. Helmerhorst told Gizmag. "We then searched over 3 million small molecules 3D structures for their ability to fit the key features within this insulin map. We found a lead drug molecule that fitted the map and mimicked insulin in specific biological assays and animal models. We have already spent nearly 10 years optimizing this lead molecule."

Unlike insulin, the small drug molecule isn't broken down in the stomach so can be taken orally as a tablet. As well as appealing to people who aren't fond of needles, Prof. Helmerhorst says a tablet would also be cheaper to produce and easier to store than insulin. This would make it easier to distribute in developing countries where the rates of diabetes are on the rise.

Although Prof. Helmerhorst says the insulin substitute could potentially replace the need for injections for sufferers of both type 1 and type 2 diabetes, because type 1 diabetics depend on insulin for their survival, the researchers plan to initially target type 2 diabetics prior to them developing full insulin dependency.

The research is still in the lead optimization stage with clinical trials not expected to begin for another five years or so. Looking for licensees to market the insulin substitute and investors to fund the next stage of development, the Curtin University team recently presented their research and generated a lot of interest at Univation 2011, which aims to showcase research being developed at West Australia's universities to potential investors.

Source: GIZMAG

The molecule has four branches that act as wheels, rotating when a tiny metal tip applied a small current to them.

With 10 electric bursts, the car was made to move six billionths of a metre.

The approach, published in Nature, joins recent single-molecule efforts, and seems to overcome the forces that often dominate at such tiny scales.

The "batteries" of the electric car come by way of the tip of what is called a scanning tunnelling microscope - an extraordinarily fine point of metal that ends in just an atom or two. As the tip draws near the molecule, electrons jump into it.

The motor of the approach lies with the four "molecular rotors" that act as the car's wheels; they undergo a change in shape when they absorb the electrons.

The demonstration is a tour de force in what is called "bottom-up" nanotechnology. A wide array of machines has been demonstrated in recent years, incorporating parts etched to minuscule sizes from chunks of metals or semiconductors - a small version of traditional, "top-down" manufacturing.

As the chemical groups in each "wheel" change shape, the car inches ahead

Building up from single, designed molecules is another matter, said Tibor Kudernac, a chemist now at the University of Twente, the Netherlands, and lead author of the paper.

"If you look around, in all biological systems are a vast number of molecular machines or rotors based on proteins that do important things very well; muscle contraction is based on protein motors," he explained.

"This is a simple demonstration that we can achieve anything like that. It's an important observation and I think it will motivate people to think about it perhaps a bit more from an application point of view."

Dr Kudernac concedes that applications for molecular machines like the car are probably far in the future. The first task, he said, was to make it work under normal conditions; the current work has been done at a blisteringly cold -266C and in a high vacuum.

And although each potential application will require a newly designed molecular machine, Dr Kudernac remains confident.

"There are ways to play around," he said. "That's what we chemists do - we try to design molecules for particular purposes, and I don't see any fundamental limitations."

Source: BBC

These creatures served as inspiration for a new dry adhesive tape that not only boasts impressive bonding strength, but can also be attached and detached thousands of times without losing its adhesive properties.

The secret to the wall climbing ability of many insects and geckos lies in the thousands of tiny hairs called setae that cover their feet and legs. The sheer abundance of these hairs, coupled with flattened tips that can splay out to maximize contact on even rough surface areas, make it sufficient for the Van der Waals forces, which operate at a molecular level and are relatively weak compared to normal chemical bonds, to provide the requisite adhesive strength that allows them to scurry along walls and ceilings.

It is this technique that the research group, led by Stanislav Gorb, have mimicked with their silicone tape. By patterning the tape with tiny hairs similar to setae, they created a tape that was at least two times harder to pull off of a surface than a flat tape of the same material. Additionally, the bioinspired tape leaves no sticky residue, can also work underwater, and can be repeatedly peeled off thousands of times without losing its ability to grip.

Providing an illustration of the adhesive properties of the new tape, a 20 x 20 cm (7.87 in) square piece was able to support the weight of one team member dangling from the ceiling.

The researchers are also looking to nature in the form of beetle coverwings, snake skin, and anti-adhesive plants, for inspiration for other bioinspired materials.

The University of Kiel team presented their findings at the AVS Symposium held in Nashville earlier this month.

Source: GizMag

The thing about growing working organs in the lab is that the whole enterprise is completely mind-blowing. Yet we just keep doing it, and so we keep blowing minds. The latest: a team of researchers at Japan’s RIKEN Center--the same group who earlier this year engineered a mouse retina that is the most complex tissue ever engineered--have now derived a working pituitary gland from mouse stem cells.

That’s saying something. For one, the pituitary gland is an integral part of the body’s endocrine system. From it’s position at the base of the brain it doles out key developmental hormones that instruct the body on how to grow and develop over time. But perhaps more importantly, the pituitary gland cannot itself develop without special chemical instructions from the hypothalamus (the brain region just above it).

That’s a serious bioengineering problem, because in order to grow a working pituitary gland in the lab you need a hypothalamus--or at least a hypothalamus analog--to tell it how to develop. The researchers overcame this with a 3-D cell culture and some good old fashioned trial and error. They had a notion of what kind of signaling factors would be needed to make a proper pituitary gland grow and tried combinations until they found the right fit.

The result is a working pituitary that expressed the right hormones and the right biomarkers. And to remove any doubt, the researchers implanted their lab-grown glands into mice with pituitary defects. The mice quickly showed restored levels of key pituitary hormones and behavioral symptoms of pituitary problems disappeared. These pituitary glands, by all appearances, seem to work like the original biological glands were meant to.

The next step is a human pituitary, though the researchers say that’s still years away. But progress is progress. If you can build a trachea and a retina and a pillar of the endocrine system in a lab, the list of things you can’t build begins to narrow.

Source: Popular Science

“This is a novel application of existing materials, and has potential for rapid, high-volume manufacturing processes or packaging applications,” says Dr. Michael Dickey, an assistant professor of chemical and biomolecular engineering at NC State and co-author of a paper describing the research.

The process is remarkably simple. Researchers take a pre-stressed plastic sheet and run it through a conventional inkjet printer to print bold black lines on the material. The material is then cut into a desired pattern and placed under an infrared light, such as a heat lamp.

The bold black lines absorb more energy than the rest of the material, causing the plastic to contract – creating a hinge that folds the sheets into 3-D shapes. This technique can be used to create a variety of objects, such as cubes or pyramids, without ever having to physically touch the material. The technique is compatible with commercial printing techniques, such as screen printing, roll-to-roll printing, and inkjet printing, that are inexpensive and high-throughput but inherently 2-D.

By varying the width of the black lines, or hinges, researchers are able to change how far each hinge folds. For example, they can create a hinge that folds 90 degrees for a cube, or a hinge that folds 120 degrees for a pyramid. The wider the hinge, the further it folds. Wider hinges also fold faster, because there is more surface area to absorb energy.

“You can also pattern the lines on either side of the material,” Dickey says, “which causes the hinges to fold in different directions. This allows you to create more complex structures.”

The researchers developed a computer-based model to explain how the process works. There were two key findings. First, the surface temperature of the hinge must exceed the glass transition temperature of the material, which is the point at which the material begins to soften. Second, the heat has to be localized to the hinge in order to have fast and effective folding. If all of the material is heated to the glass transition temperature, no folding will occur.

“This finding stems from work we were doing on shape memory polymers, in part to satisfy our own curiosity. As it turns out, it works incredibly well,” Dickey says.

Source: North Carolina State University

Citation: The Futurist, Nov-Dec 1989 v23 n6 p14(5)

------------------------------------------------------------------------------

Title: The birth of the geodesic dome; how Bucky did it. (R. Buckminster Fuller)

Authors: Sieden, Lloyd Steven

------------------------------------------------------------------------------

Subjects: Geodesic domes_research & Dwellings_innovations

People: Fuller, R. Buckminster_innovations

Reference #: A8121293

=============================================

Richard Buckminster Fuller, c. 1917.

Born: July 12, 1895

Milton, Massachusetts, United States

Died: July 1, 1983 (aged 87)

Los Angeles, United States

Occupation: designer, author, inventor

Spouse: Anne Fuller

Children 2: Allegra Fuller Snyder and Alexandra who died in childhood

Full Text COPYRIGHT World Future Society 1989

The Birth of The Geodesic Dome

Although Buckminster Fuller invariably maintained that he was a comprehensivist who was interested in almost everything, his life and work were dominated by a single issue: shelter and housing. Even as a young boy in the early 1900s, Fuller--who preferred to be called Bucky--was constructing rudimentary structures and inventing better "environment controlling artifacts."

The practical culmination of his quest to employ modern assembly-line manufacturing techniques and the best man-made materials in producing inexpensive, elegant housing came toward the end of World War II. At that time, government officials contracted Fuller to build two prototype Dymaxion Houses at the Beech Aircraft Company in Wichita, Kansas.

The lightweight, circular houses were praised by all who toured them. Because the Dymaxion House was to provide many new innovations at the very affordable suggested retail price of $6,500, orders flowed into the factory before plans for distribution were seriously considered. However, Fuller's interests were not geared toward practical matters such as financing and marketing, and the

Dymaxion House never advanced beyond the prototype stage. Fuller then moved on to consider other innovations that could benefit humanity in the areas of structure and housing.

He also returned to his less pragmatic quest to discover nature's coordinate system and employ that system in a structure that would, because it was based on natural rather than humanly developed principles, be extremely efficient. That structure is the geodesic dome, which, because it approximates a sphere, encloses much more space with far less material than conventional buildings.

In order to uncover nature's coordinate system, Fuller retreated from a great deal of his usual activities during 1947 and 1948. The primary focus of that retreat was a single topic: spherical geometry. He chose that area because he felt it would be most useful in further understanding the mathematics of engineering, in discovering nature's coordinate system, and eventually in building the spherical structures that he found to be the most efficient means of construction.

Dome Models

Having observed the problems inherent in conventional construction techniques (as opposed to the ease with which nature's structures are erected) and the indigenous strength of natural structures, Fuller felt certain that he could perfect an analogous, efficient, spherical-construction technique. He was also aware that any such method would have to be predicated upon spherical trigonometry. To do that, Bucky converted the small Long Island apartment that his wife, Anne, had rented into a combination workshop and classroom where he studied and discussed his ideas with others.

As those ideas started to take shape in the models and drawings he used for sharing his insights, Fuller considered names for his invention. He selected "geodesic dome" because the sections or arcs of great circles (i.e., the shortest distance between two points on a sphere) are called geodesics, a term derived from the Greek word meaning "earth-dividing." His initial dome models were nothing more than spheres or sections of spheres constructed from crisscrossing curved pieces of material (each of which represented an arc of a great circle) that formed triangles. Later, he expanded the concept and formed the curved pieces into even more complex structures such as tetrahedrons or octahedrons, which were then joined to create a spherical structure. Still, the simple triangulation of struts remained, as did the initial name of the invention.

Although Fuller's study of mathematics played a significant role in his invention of the geodesic dome, that process was also greatly influenced by his earlier extensive examination of and work within the field of construction. During his construction experience, he came to realize that the dome pattern had been employed, to some extent, ever since humans began building structures. Early sailors landing upon foreign shores and requiring immediate shelter would simply upend their ships, creating an arched shelter similar to a dome.

Land-dwelling societies copied that structure by locating a small clearing surrounded by young saplings and bending those uncut trees inward to form a dome that they covered with animal skins, thatch, or other materials. Over time, that structure developed into the classic yurt that still provides viable homes for many people in and around Afghanistan and the plains of the Soviet Union.

TO BE CONTINUED...

... CONTINUES.

A New Form of Architecture

In 1948, the geodesic dome was far from the amazingly sophisticated structure it would become only a few years later. In fact, it consisted primarily of Bucky's idea and an enormous pile of calculations he had formulated.

Although Fuller was developing and studying the geodesic dome using small models, he was eager to expand his understanding through the construction of larger, more-practical projects. Thus, when he was invited to participate in the summer institute of the somewhat notorious Black Mountain College in the remote hills of North Carolina near Asheville, Fuller eagerly accepted. He had lectured at that rather unorthodox institution the previous year and had been so popular that he was asked back for the entire summer of 1948.

When he was not delivering lengthy thinking-out-loud lectures that summer, Fuller's primary concern was furthering an entirely new form of architecture. In his examination of traditional construction, he had discovered that most buildings focused on right-angle, squared configurations.

He understood that early human beings had developed that mode of construction without much thought by simply piling stone upon stone. Such a simplistic system was acceptable for small structures, but when architects continued mindlessly utilizing that same technique for large buildings, major problems arose. The primary issue created by merely stacking materials higher and higher is that taller walls require thicker and thicker base sections to support their upper sections. Some designers attempted to circumvent that issue by using external buttressing, which kept walls from crumbling under the weight of upper levels, but even buttressing limited the size.

Fuller found that the compression force (i.e., pushing down) that caused such failure in heavy walls was always balanced by an equal amount of tensional force (i.e., pulling, which in buildings is seen in the natural tendency of walls to arc outward) in the structure. In fact, he discovered that if tension and compression are not perfectly balanced in a structure, the building will collapse. He also found that builders were not employing the tensional forces available. Those forces are, instead, channeled into the ground, where solid foundations hold the compressional members, be they stones or steel beams, from being thrust outward by tension. Always seeking maximum efficiency, Fuller attempted to employ tensional forces in his new construction idea. The result was geodesic structures.

Because Bucky could not afford even the crude mechanical multiplier machines available during the late 1940s and was working with nothing but an adding machine, his first major dome required two years of calculations. With the help of a young assistant, Donald Richter, Fuller was, however, able to complete those calculations. Thus, he brought most of the material needed to construct the first geodesic dome to Black Mountain in the summer of 1948.

A Dymaxion House at The Henry Ford.

Disappointment before Success

His vision was of a 50-foot-diameter framework fabricated from lightweight aluminum, and, working with an austere budget, he had purchased a load of aluminum-alloy venetian-blind strips that he packed into the car for the trip to the college. Over the course of that summer, Bucky also procured other materials locally, but he was not completely satisfied with the dome's constituent elements, which were neither custom-designed for the project nor of the best materials. Still, with the help of his students, the revolutionary new dome was prepared for what was supposed to be a quick assembly in early September, just as the summer session was coming to an end.

The big day was dampened by a pouring rain. Nonetheless, Bucky and his team of assistants scurried around the field that had been chosen as the site of the event, preparing the sections of their dome for final assembly, while faculty and students stood under umbrellas, watching in anticipation from a nearby hillside. When the critical moment arrived, the final bolts were fastened and tension was applied to the structure, causing it to transform from a flat pile of components into the world's first large geodesic sphere. The spectators cheered, but their excitement lasted only an instant as the fragile dome almost immediately sagged in upon itself and collapsed, ending the project.

Although he must have been disappointed that day, Bucky's stoic New England character kept him from publicly acknowledging such emotion. Instead, he maintained that he had deliberately designed an extremely weak structure in order to determine the critical point at which it would collapse and that he had learned a great deal from the experiment. Certainly, the lessons learned from that episode were valuable, and his somewhat egocentric rationale was by no means a blatant lie. However, had he really been attempting to find the point of destruction, Bucky would have proceeded, as he did in later years, to add weights to the completed framework until it broke down.

In his haste to test his calculations, Fuller had proceeded without the finances necessary to acquire the best materials. Because of the use of substandard components, the dome was doomed to failure, and a demonstration of the geodesic dome's practical strength was condemned to wait another year.

During that year, Fuller taught at the Chicago Institute of Design. He and his Institute students also devoted a great deal of time to developing his new concepts. It was with the assistance of those design students that Fuller built a number of more successful dome models, each of which was more structurally sound than the previous one.

Then, when he was invited to return to Black Mountain College the following summer as dean of the Summer Institute, Fuller suggested that some of his best Chicago Institute students and their faculty accompany him, so that they could demonstrate the true potential of geodesic domes.

Having earned some substantial lecture fees during the previous year, Bucky was able to purchase the best of materials for his new Black Mountain dome. The project was a 14-foot-diameter hemisphere constructed of the finest aluminum aircraft tubing and covered with a vinyl-plastic skin. Completely erected within days after his arrival, that dome remained a stable fixture on the campus throughout the summer. To further prove the efficiency of the design to somewhat skeptical fellow instructors and students, Bucky and eight of his assistants daringly hung from the structure's framework, like children on a playground, immediately after its completion.

TO BE CONTINUED...

The Ford Dome

In 1953, Fuller and his geodesic dome were elevated to international prominence when the first conspicuous commercial geodesic dome was produced. That structure was erected in answer to a Ford Motor Company problem believed to be insoluble. During 1952, Ford was in the process of preparing for its fiftieth anniversary celebration the following year, and Henry Ford II, grandson of Henry Ford and head of the company, decided he wanted to fulfill one of his grandfather's dreams as a tribute to the company's founder. The senior Ford had always loved the round corporate headquarters building known as the Rotunda but had wanted its interior courtyard covered so that the space could be used during inclement Detroit weather.

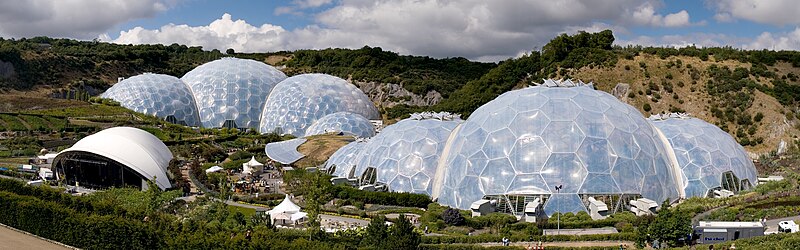

Panoramic view of the geodesic domes at the The Eden Project

Unfortunately -- but fortunately for Bucky -- the building was fairly weak. It had originally been constructed to house the Ford exhibition at the Chicago World's Fair of 1933, but Henry Ford had so loved the building that he had had it disassembled and shipped in pieces to Dearborn, where it was reconstructed. Having been designed as a temporary structure, the fragile Rotunda building could not possibly support the 160-ton weight that Ford's engineers calculated conventional steel-frame dome would require. Under such pressure, the building's thin walls would have immediately collapsed.

Still, Henry Ford II was a determined person, and he wanted the courtyard covered. Consequently, Ford management and engineers continued searching for an answer until someone suggested calling Buckminster Fuller. By that time, Fuller's work drawing international attention, and although his geodesic dome had yet to be proven effective in an industrial project, desperate Ford officials decided they should at least solicit Bucky's opinion. When he arrives at the Detroit airport, Fuller was greeted by a Ford executive in a large limousine who treated him like royalty, quickly escorting him to the Rotunda building for an inspection. After a short examination of the 93-foot opening requiring a dome, Ford management asked the critical question: Could Fuller build a dome to cover the courtyard? With no hesitation, Bucky answered that he certainly could, and the first commercial geodesic dome began to take shape.

The Ford executives next began to question the specifications of Fuller's plan. When they asked about weight, he made some calculations and answered that his dome would weigh approximately 8.5 tons, a far cry from their 160-ton estimate. Ford management also requested a cost estimate and advised Fuller that, because of the upcoming anniversay celebration, the dome had to be completed within the relatively short period of a few months. When Fuller's price was well below Ford's budget and he agreed to construct the dome within the required time frame, he was awarded a contract.

The agreement was signed in January of 1953, and Bucky immediately began working to meet the April deadline. The somewhat discredited Ford engineers who had failed to develop a practical solution were, however, not convinced that the obscure inventor's fantastic claims were valid. Thus, they began working on a contingency plan that would prevent further reputations further, the engineers secretly contracted another construction firm to hastily haul away any evidence of Fuller's work when he failed. The Ford engineers were once again proven wrong when the dome was successfully completed in April, two days ahead of schedule.

Building from the Top Down

Actual construction of the dome was a marvel to behold. Reporters from around the world gathered to witness and recount the architectural effort as well as Ford's anniversary celebration. Because the courtyard below the dome was to be used for a television special commemorating the anniversary, and because business at Ford had to proceed normally, Fuller's crew was provided with a tiny working area and instructed to keep disruptions to a minimum.

Ford management was also concerned with the safety of both the dome workers and the people who might wander beneath the construction. They anticipated that problems would arise when Ford employees, television crews, reporters, and spectators gathered below to observe the construction workers climbing high overhead on the treacherous scaffolding, but once again Bucky surprised everyone. Instead of traditional scaffolding, he employed a strategy similar to the one he developed in 1940 for the quick assembly of his Dymaxion Deployment Units.

Because the sections of the dome were prefabricated and then suspended from a central mast, no dangerous scaffolding was required. The construction team worked from a bridge erected across the top of the Rotunda courtyard. Like Dymaxion Deployment Units, the Ford dome was then built from the top down while being hoisted higher and rotated each time a section was completed. The dome was assembled from nearly 12,000 aluminum struts, each about three feet long and weighing only five ounces. Those struts were preassembled into octet-truss, equilateral-triangular sections approximately 15 feet on a side. Since each section weighed only about four pounds and could be raised by a single person, no crane or heavy machinery was required to hoist them to the upper bridge assembly area.

Once on the working bridge, the identical sections were riveted into place on the outwardly growing framework until it covered the entire courtyard. Upon completion, the 8.5-ton dome remained suspended on its mast, hovering slightly above the building itself until the mooring points were prepared. Then, it was gently lowered down onto the Rotunda building structure with no problem.

To complete the first commercial geodesic dome, clear Fiberglas "windows" were installed in the small triangular panels of the framework. Because Fuller had not yet developed or determined the best means of fastening those panels, they would eventually be a cause of the destruction of the dome and the building itself.

Since it was the first large functional geodesic dome, many aspects of the Ford dome were experimental. They had been tested in models, but how the dome and the materials utilized would withstand the forces of Michigan winters could be determined only by the test of time. The Rotunda building dome did perform successfully for several years before the elements began taking their toll and leaks between the Fiberglas and the aluminum began to occur. Still, with regular maintenance, that problem was not serious, and convening corporate events under the dome became a tradition. One of those events was the annual Ford Christmas gathering.

In 1962, numerous leaks in the dome were noticed as the Christmas season approached, and a maintenance crew was dispatched one cold late-autumn day to repair the problem. The temperature was, however, too cold to permit proper heating of the tar they used for the repairs, and, in a common practice, the workers added gasoline to thin the tar. They were warming the tar with a blowtorch when that potent mixture ignited, and the building quickly caught fire. Since the building had never been planned as a permanent structure, it was not long before the entire Rotunda was engulfed in flames that destroyed the first commercial geodesic dome, the singular structure that, more than any other, had catapulted Fuller to public fame.

Doing More with Less

The notoriety provided by the Ford project resulted in an enormous amount of nearly instant public interest in Fuller and his ideas. It also brought him to the attention of a group of scientists who were struggling with another seemingly unsolvable problem: protection of the Distant Early Warning Line radar installations throughout the Arctic. Once again, Fuller and his amazing geodesic dome surprised all the experts as his hastily invented Fiberglas "radomes" proved more than able to handle that difficult task.

The proliferation of radomes in technologically advanced situations around the world moved the geodesic dome into its rightful position as a symbol of developing humanity doing more and more with fewer resources. Thus, geodesic domes are now employed for diverse tasks such as providing a more natural structure for children on playgrounds, covering athletic stadiums, and being proposed for use in future space construction.

However, the true significance of the geodesic dome is most evident in the fact that it is often the dominant symbol employed at major future-oriented expositions. When most people remember the 1967 Montreal World's Fair, the 1986 Vancouver World's Fair, or Disney's EPCOT Center, the first image they recall is the geodesic dome.

It properly stands as a monument to the work of Buckminster Fuller, who successfully shared his vision of a world that works for everyone. He also inspired scores of people to work, as he did, to establish a network of equally significant individuals supporting humanity's emergence into a new era of cooperation. That relationship between individual human beings, as well as that between humans and their environment, is not modeled by the rigid conventional buildings that fill our environment. It is modeled in the amazing geodesic dome's network of lightweight, resilient struts, wires, and panels.

Lloyd Steven Sieden is an author, lecturer, and consultant whose primary concentration is helping businesses, organizations, and individuals apply Buckminster Fuller's ideas and solutions to practical issues. His address is Sieden & Associates, 32921 Avenida Descanso, San Juan Capistrano, California 92675.

This article is adapted from his book Buckminster Fuller's Universe: An Appreciation (Plenum Press, 1989), which is available from the Futurist Bookstore. See page 42 for details.

=============================================

THE END.

Source: insite.com

Technology for making an "artificial leaf" holds the potential for opening an era of "fast-food energy," in which people generate their own electricity at home with low-cost equipment perfect for the 3 billion people living in developing countries and even home-owners in the United States. That's among the prospects emerging from research on a new genre of "electrofuels" described in the current edition of Chemical & Engineering News, the American Chemical Society's weekly newsmagazine.

In the article, C&EN Senior Correspondent Stephen K. Ritter describes research on electrofuels, made by using energy from the sun and renewable ingredients like water and carbon dioxide, reported at a gathering of experts sponsored by the U. S. Department of Energy's Advanced Research Projects Agency (ARPA-E). Created in 2009 by the American Recovery & Reinvestment Act, ARPA-E is funding electrofuels research, with the goal of developing technologies that improve on nature's approach — photosynthesis. Electrofuels is one of 12 programs funded by ARPA-E.

The artificial leaf is one of the electrofuels technologies. Made of inexpensive materials, the leaf breaks down ordinary water into the oxygen and hydrogen that can power an electricity-producing fuel cell. Just drop the credit-card-sized device into a bucket of water and expose it to sunlight. With the cost-conscious technology, one door-sized solar cell and three gallons of water could produce a day's worth of electricity for a typical American home. The article describes a range of other electrofuel technologies, including ones based on engineered microbes, being developed in the quest for new ways of making fuels.

Source: PhysOrg - via ZeitNews

|